Yokogawa Electric Corporation announces the development of the OpreX™ Battery Web Gauge ES-5, set to be released in January 2025 as part of the OpreX Quality Control System family.

**Development Background**

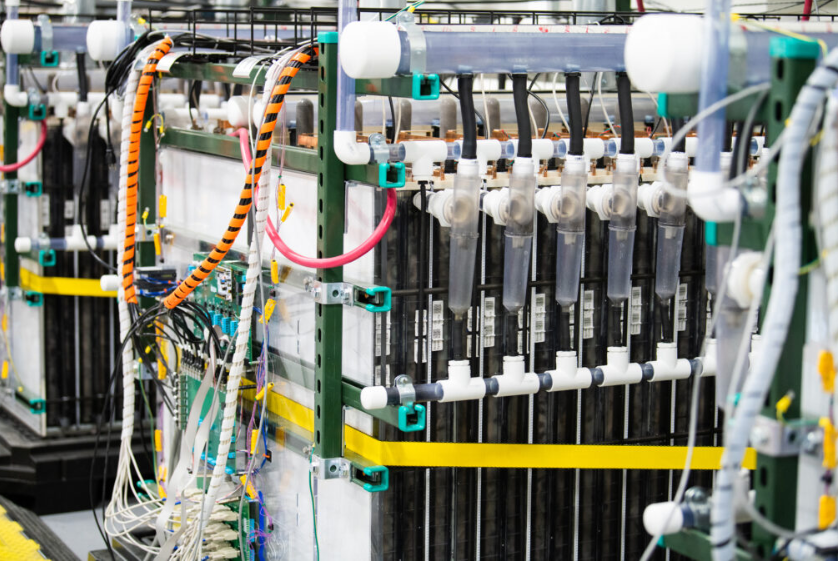

Since the introduction of its first online thickness gauge for sheet manufacturing equipment in 1962, Yokogawa has built a solid reputation in this market by consistently developing new versions of these products. These gauges are used in final production processes to continuously measure and control thickness, weight, color, and other characteristics of sheet materials such as paper and film. The WEBFREX3ES, designed for electrode sheet production for lithium-ion and other battery types, has been widely adopted by major battery manufacturers globally.

With the global shift towards electric vehicles, the demand for rechargeable batteries is increasing rapidly. Battery manufacturers are also seeking to reduce CO2 emissions from their production processes and improve productivity in a competitive market. The OpreX Battery Web Gauge ES-5 was developed to address these needs while retaining all the features of the WEBFREX3ES.

**Main Features**

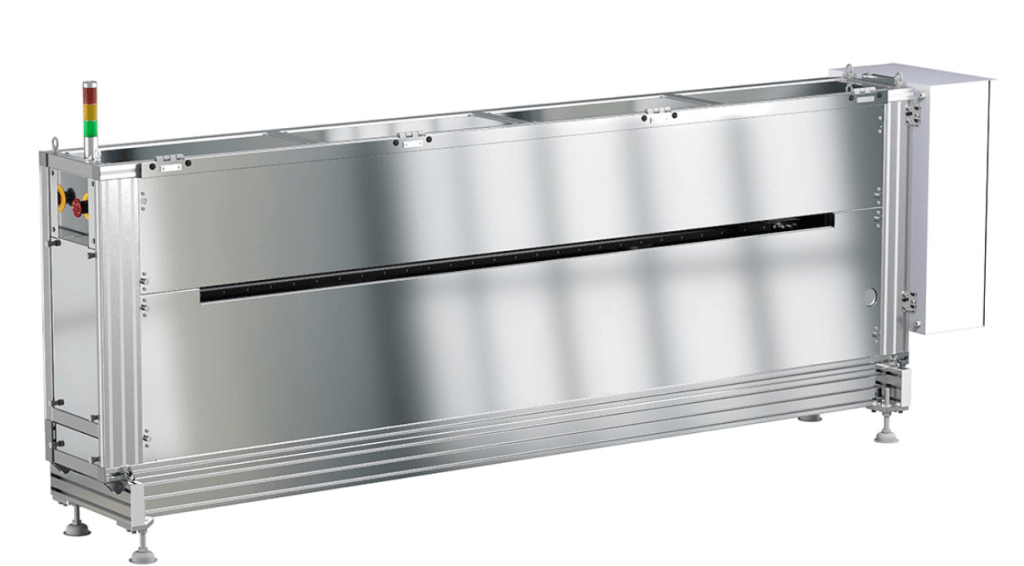

+ **Energy efficiency**: The box-type frame of the OpreX Battery Web Gauge ES-5 reduces power consumption by over 50%, weighs 75% less, and reduces air consumption volume by 90% compared to the WEBFREX3ES. This results in reduced CO2 emissions on the battery production line and in the supply chain.

+ **Overall optimization**: The OpreX Battery Web Gauge ES-5 uses the OpreX Collaborative Information Server as its centralized information management platform. This platform collects data from plant equipment and systems used in various peripheral processes to ensure an even coating on electrode sheets, crucial for rechargeable battery performance and quality. This enhances production efficiency by linking with these peripheral processes and enables a shift from optimizing individual processes to optimizing the entire production line.

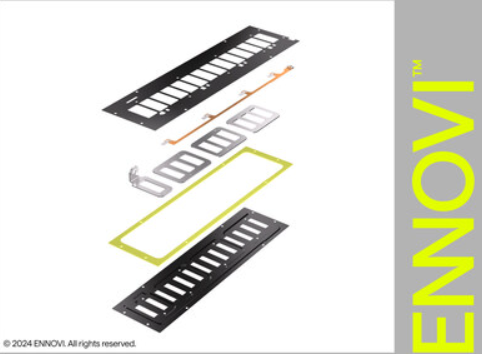

+ **Safe and secure quality monitoring**: The OpreX Battery Web Gauge ES-5 features a safe design to minimize risks that could cause fires in rechargeable batteries by reducing exposure to copper and other metal powders. It offers an industry-leading 3-second scanning speed for the 1,500 mm scan width, achieves high-density measurement of up to 1,600 points widthwise, and has a minimum 5 mm slit width resolution, enabling meticulous quality control. The new sensor design and box-type frame with a safety cover over the sensor moving parts reduce the risk of contact during operations and maintenance, and the radiation-controlled area is less than half that of the WEBFREX3ES, enhancing safety in operation and maintenance.

**Major Target Markets**

Batteries, multilayer ceramic capacitors, electrical machinery/electronics

**Applications**

Online measurement of coating thicknesses in production lines for products such as battery electrodes and multilayer ceramic capacitors

For more information, visit www.yokogawa.com

Source

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?