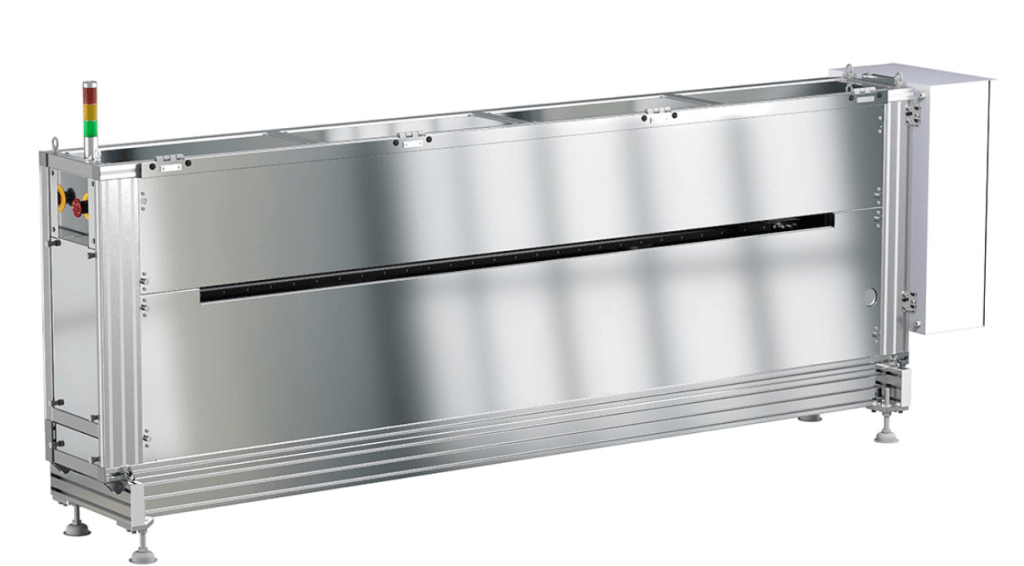

As the EV industry moves to 800-volt architectures, battery testing consumes more power than ever, increasing manufacturing footprints. To combat this, Unico has developed a solution: The Quantum Drive Platform, which recirculates the power between testing channels, optimizing power consumption and reducing footprint.

The platform also allows for a single grid connection to test multiple cells, modules, packs, motors, chargers, and other powertrain components, further simplifying the testing process.

We interviewed Don Wright, VP of Engineering at Unico on how it works:

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

Can you walk us through the Quantum Drive Platform?

A few years ago an 800-volt test system was more than enough because most OEMs were running 400-volt packs. As the industry shifts to 800-volt packs, Unico developed a 1200-volt test system with new technologies like silicon carbide to keep the size of the system down, while maintaining the high power and high dynamics needed. The problem is that your energy consumption and manufacturing footprint increase as you move up in power, further compounded by the higher vehicle volumes that we’re seeing today.

With the Quantum Drive Platform, we can put multiple battery testers into one system and synchronize it so that when you discharge one pack, it recirculates that power to charge another pack, what we call ‘back-to-back’ testing.

For example, if you have four channels, instead of requiring 1.6 megawatts, you may only need 400 kilowatts because you’re recirculating that energy, which is becoming increasingly important when working with power-hungry 800-volt packs.

The system can also connect to a battery energy storage system (BESS) to store and reuse that test energy down the road, further reducing power consumption. Additionally, users can test multiple cells, modules, or packs in the same system with a single connection to the grid.

(See the bottom of this article for the full battery testing specifications)

The Quantum Drive Platform can also test EV inverters, motors, and DC fast chargers, all in one system:

It’s FPGA controlled, so we can run complex control algorithms using model-based programming, allowing us to do very advanced testing that our customers request.

Can you give us an example of an advanced testing situation?

eVTOLs, for example, need very advanced propeller profiles. While the motor pivots from vertical to horizontal, the loads rapidly change, and we can model this in our controller. Our dyno can put that motor through the same loads as if it were airborne, allowing the manufacturer to test scenarios to ensure the control architecture responds appropriately to return the vehicle to the ground safely.

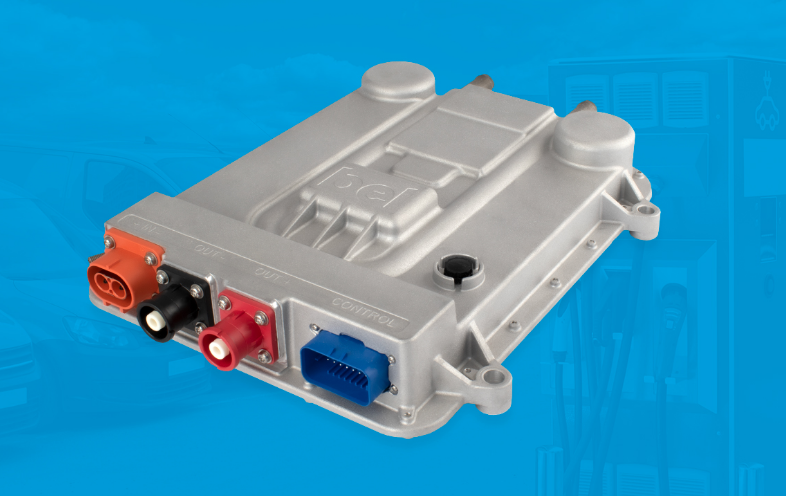

Unico recently acquired Present Power Systems, what’s coming from this acquisition?

Milwaukee-based Present Power Systems manufactures ultra-compact power electronics for EVs. Unico is set to offer a comprehensive suite of technologies for battery cell, module, and pack testing, alongside innovative EV charging solutions such as home chargers, DC fast charging stations, On-Board Chargers (OBC), DC-to-DC converters, and inductive wireless charging technologies using this new technology we’ve gained.

One upcoming product we can talk about is a home charging station that allows you to use a 110-volt standard outlet, store that power, and later charge with level 2 power without the costly purchase and installation. It’s based on the groundbreaking topology that the CEO of Present Power Systems created, and we’re excited to integrate this into our suite of EV products.

Battery testing specifications

For DC battery testing, the platform supports:

Battery Packs:

- 800V, 1200V battery platforms natively with higher voltages of 1500V or 2000V with devices in series (performance to be confirmed in Q3 2023).

- DC power in blocks of 200kW with up to 2 MW as standard configurations.

- Mix-and-match voltage and power channels in a single system possible.

- Current Rise times from 10-90% in 1ms.

- Seamless transition from charge to discharge.

- 75kHz switching frequency utilizing SiC technology.

- Current, voltage, and power control modes.

- Full channel-to-channel isolation for multi-channel battery pack testing without battery isolation monitoring conflict.

- Open communication protocols (CAN, Modbus, EtherCAT, Ethernet, etc.) for usage with most 3rd party automation platforms.

Battery Modules:

- 20-200V battery modules natively with 400V modules supported with devices in series (performance to be confirmed in Q3 2023)

- DC power in blocks of 200kW with up to 2 MW as standard configurations

- Current Rise times from 10-90% in 1ms

- Seamless transition from charge to discharge

- 75kHz switching frequency utilizing SiC technology

- Current, voltage, and power control modes

- Open communication protocols (CAN, Modbus, EtherCAT, Ethernet, etc.) for usage with most 3rd party automation platforms

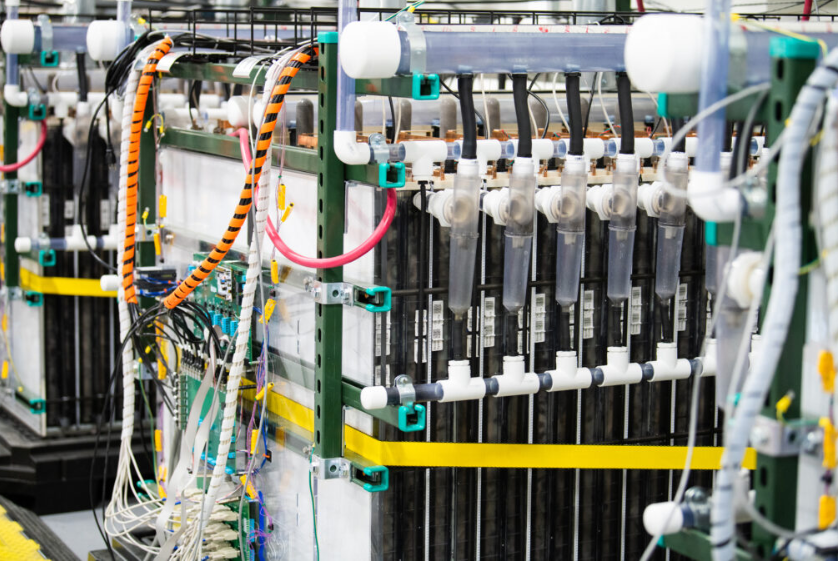

Battery Cells

(Four power ranges available)

- Coin Cell

- Voltage Range: 0-10VDC

- Current Range: -20mA to 20mA

- Power: 250mW per channel

- Current Rise times from 10-90% in 1ms

- 128 channels per 2HU 19” Rack Mount device

- Suitable for coin cell testing and BMS development as battery cell emulator

- Low Current

- Voltage Range: 0-10VDC

- Current Range: -10A to 10A

- Power: 100W per channel

- Current Rise times from 10-90% in 1ms

- 64 channels per 2HU 19” Rack Mount device

- Suitable for cylindrical/small format cell testing and BMS development as battery cell emulation

- Medium Current

- Voltage Range: 0-10VDC

- Current Range: -150A to 150A

- Power: 1500W per channel

- Current Rise times from 10-90% in 1ms

- 8 channels per device

- Channels can be paralleled up to 1200A (8x150A)

- Suitable for medium/large format cell testing

- High Current

- Voltage Range: 0-10VDC

- Current Range: -300A to 300A

- Power: 2000W per channel

- Current Rise times from 10-90% in 1ms

- 8 channels per 2HU 19” Rack Mount device

- Channels can be paralleled up to 2400A (8x300A)

- Suitable for medium/large format cell testing

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?