Interview with Sravan Vanaparthy – Vice President & GM, Industrial Power Division, Power Solutions Group, onsemi

Could you give us an introduction to the new modules?

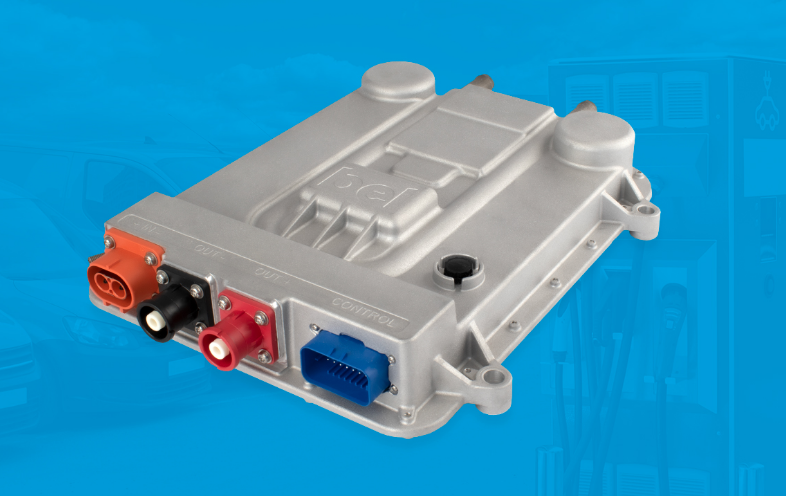

At CES 2024, onsemi unveiled the newest line of EliteSiC power-integrated modules for EV charging stations, which integrates our latest generation silicon carbide MOSFETs, the ‘M3S’. The lineup has nine different module options, with various RDS(on), package sizes, and configurations to meet different end-market needs.

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

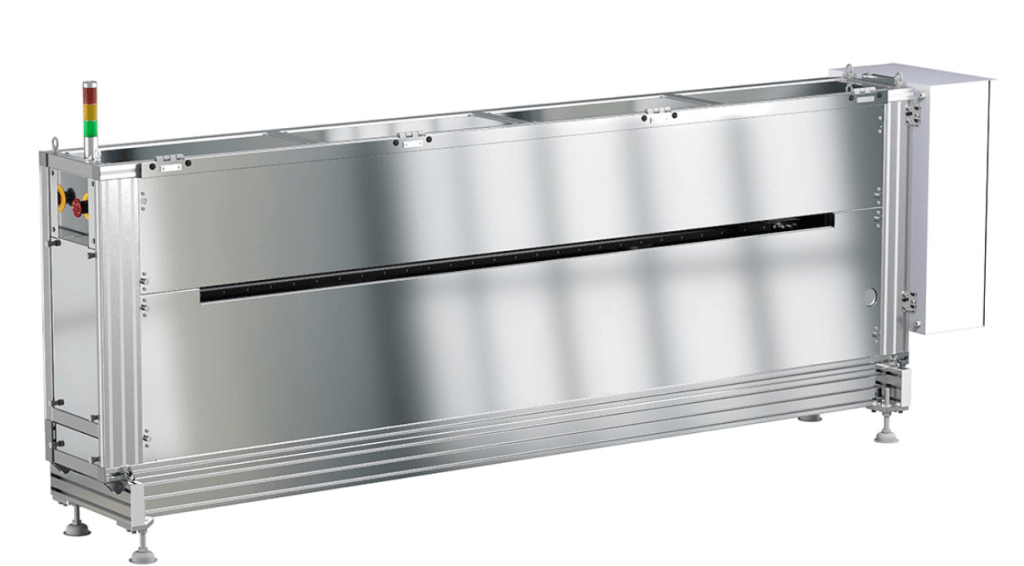

To speak on the variety, for example, highway chargers range anywhere from 200 to 350 kilowatts, and within that range, different regions and end markets have varying power needs and design architectures based on the system needs. Customers may look into one of the smaller size or higher drain-source on-resistance (RDS(on)) modules to design 30-40 kilowatt medium power racks, or the lowest RDS(on) with the highest available density for 60-70 kilowatt power racks.

The lineup includes both unidirectional and bidirectional options, depending on the level of functionality and cost sensitivity.

All of the modules are scalable from 400V, 800V, or even 1,000V systems addressing a wide range of battery pack needs from passenger to fleet vehicles. Our portfolio offers flexibility in terms of output voltage, which allows us to cater to various power requirements.

Can you talk about the M3S MOSFETs?

The M3S is our latest generation MOSFET, specially designed for high-switching applications with technology optimized for lower switching losses. Some charging applications are focused on efficiency, while others are looking for the best density versus cost, so our team optimized our silicon carbide technology and modules to suit various end cases.

One of the differentiating factors is how we design modules with the end use in mind. For example, EV traction motors need lower frequencies of operations, with fixed inductance, short circuit capability, robustness, etc. In the case of EV chargers, however, we’re converting AC power to usable DC power to charge a battery, which is primarily a resistive type of load. There is no need for short circuit handling or avalanche capability, so we focus on power loss optimization design based on end application trade-offs. We designed the M3S to minimize switching losses, due to the high frequencies.

This newest generation MOSFET builds on the previous (M2S) generation by decreasing the RDS(on) by about 15-20%. This allows the charging station manufacturers to increase the power density of their end systems using the same module sizes as the previous generation.

Can you talk about some of the weight and size reductions?

Utilizing our latest generation M3S SiC-based modules enables a 40% reduction in volume and 52% in weight compared to an IGBT-based design. This is a significant reduction in size, weight, and power dissipation thanks to high-density SiC modules, especially for high-power charging applications. Due to its device structure and wide band gap materials, it operates at a much higher efficiency with lower losses. Some of our customers can use two fans instead of four and switch to air cooling instead of liquid.

Additionally, when you increase the frequency of a device or power circuit, you use fewer passives like inductors and capacitors, saving size, weight, and cost.

Given the rapid charging infrastructure rollouts, how are the modules helping with the increased grid demand?

EV adoption continues to grow, however, the industry has a massive infrastructure gap, especially in terms of ultrafast charging stations.

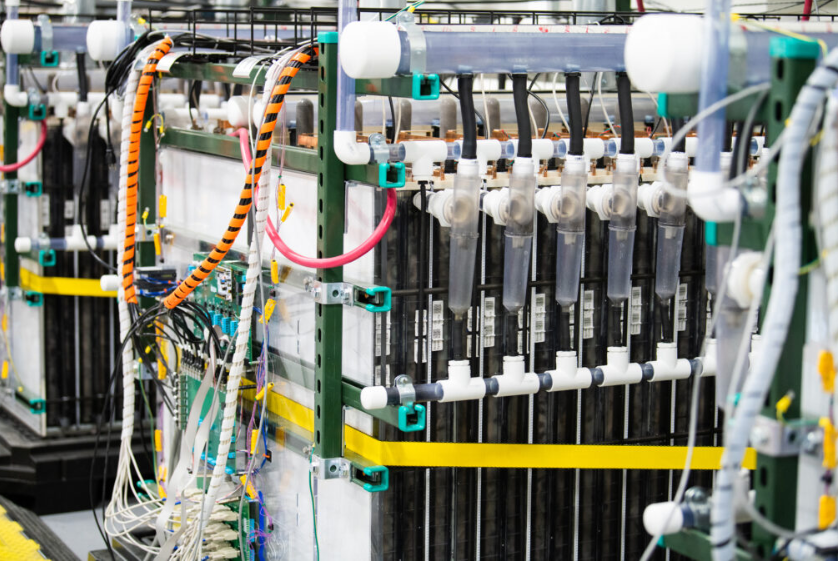

The EV charging infrastructure needs to quadruple by 2025, and octuple by 2030. Charger rollouts are being driven by government incentives and OEM investment, but the grid needs to be ready as well, which is why we offer the bidirectional capability in our integrated SiC Modules.

Several customers are designing bidirectional charging stations as a “distributed grid system”, integrating a solar source, energy storage, and a charging station all in one, which can help reduce reliance on the grid by producing some of its own energy and storing it. Especially by taking advantage of storing energy during off-peak hours and using it during peak hours to have significant savings in energy costs. Bidirectional charging increases the ROI for charging station manufacturers.

Can you talk about reliability testing?

Customers expect long-term reliability given the harsh environments the modules are put through. Depending on the station’s location and demand, it’s typically going through several more load cycles than an EV vehicle would. We design the modules by optimizing the layout parasitics, adding enough density to match the high levels of power cycles, enabling longer operating cycles for an EV charger. Any downtime is a loss to our customers, so the reliability of the modules is our top priority in the design, validation, and testing of our SiC modules. In all of our designs and reliability testing, we exceed the standards and expect long-term performance.

Can you touch on the simulation tools for design engineers?

Piecewise linear electrical circuit simulation (PLECS) is a flexible self-service design tool available on our website for all of our customers and end users. It has been a very successful feature with a lot of great feedback.

It’s software for designing high-power conversion applications, where we provide all of the models of our modules, SiC & IGBT discrete portfolio. Customers can add their requirements such as input voltages, output loads, ambient temperature, exterior requirements, etc., and choose the model that fits their needs.

Instead of hardware trial and error, design engineers can simply log in, do their scaling requirements in terms of temperature, load profile, etc., and come up with the right product to design the hardware around, speeding up time to market.

The self-service simulator feature we offer in our EliteSiC simulator allows customers to modify the model to adapt to their real application environment by modifying the parasitic inductances and resistance to simulate more accurate losses that are close to the end system.

When will we see the modules in the market?

All the modules announced at CES are now in volume production and available for customer samples through our website.

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?