Audi has announced the production of its first fully electric high-volume model, the Q6 e-tron series, at its German site in Ingolstadt. The company is also assembling the newly developed high-voltage (HV) battery for the Premium Platform Electric (PPE) at its headquarters, expanding its manufacturing capabilities for fully electric models.

To produce the Q6 e-tron, the company is assembling approximately 1,000 HV batteries daily in its 30,000-square-meter facility. The manufacturing time for each HV battery has been reduced from two hours to 55 minutes, with an automation rate of about 90 percent.

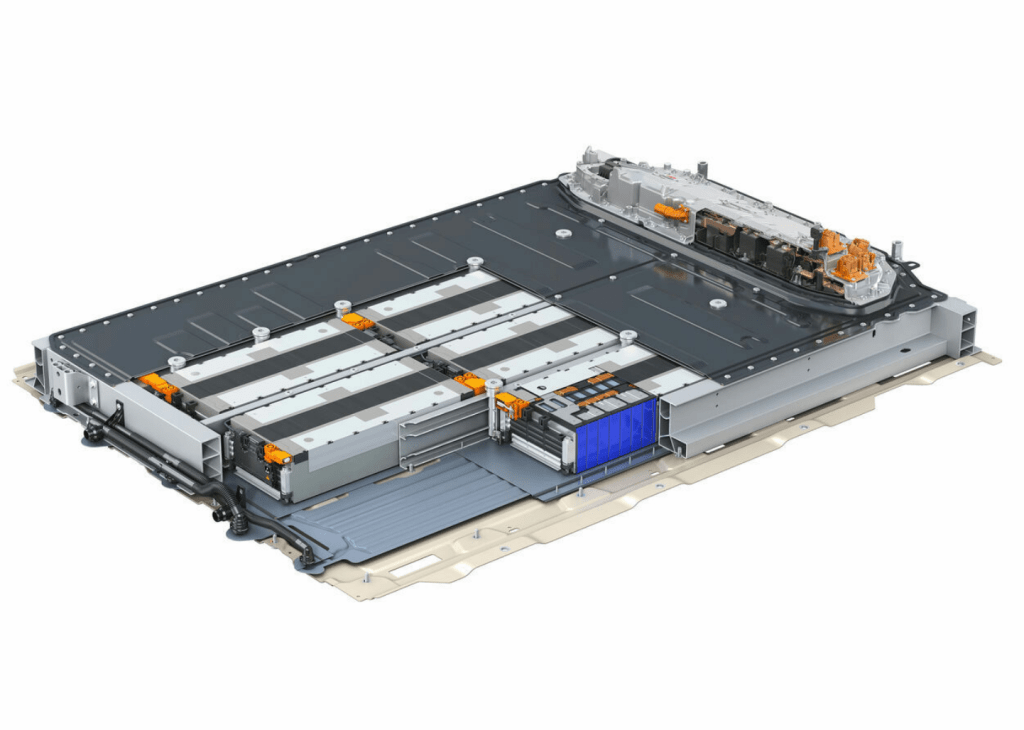

The PPE battery consists of only twelve modules with a total of 180 prismatic cells, a significant reduction compared to the 36 modules and 432 cells in the Q8 e-tron’s HV battery. This change aligns with the system voltage of 800 volts to balance range and charging performance. The PPE battery’s composition is approximately 8:1:1 for nickel, cobalt, and manganese, respectively, with a reduced proportion of cobalt and an increased proportion of nickel, enhancing the energy density.

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

The PPE battery’s reduced module count offers several advantages, including less installation space, lighter weight, better integration into the vehicle’s crash structure and cooling system, fewer cables and high-voltage connectors, and significantly fewer bolted fastenings. The battery housing includes an integrated cooling plate for homogeneous heat transfer and optimal battery conditioning. The protective side skirts are securely attached to the body, not the battery, and the underbody cladding is made of a new fiber composite material, further reducing weight and improving thermal insulation.

The HV battery for the PPE, developed from scratch, has a gross storage capacity of 100 kWh (94.9 net) and a maximum charging power of 270 kW. A variant with a capacity of 83 kWh is also available for the Audi Q6 e-tron series. Thanks to optimized cell chemistry and high-performance thermal management, the 100 kWh battery can be charged from 10 to 80 percent in 21 minutes at a suitable fast-charging station. A range of up to 255 kilometers (158 mi) can be recharged in only ten minutes.

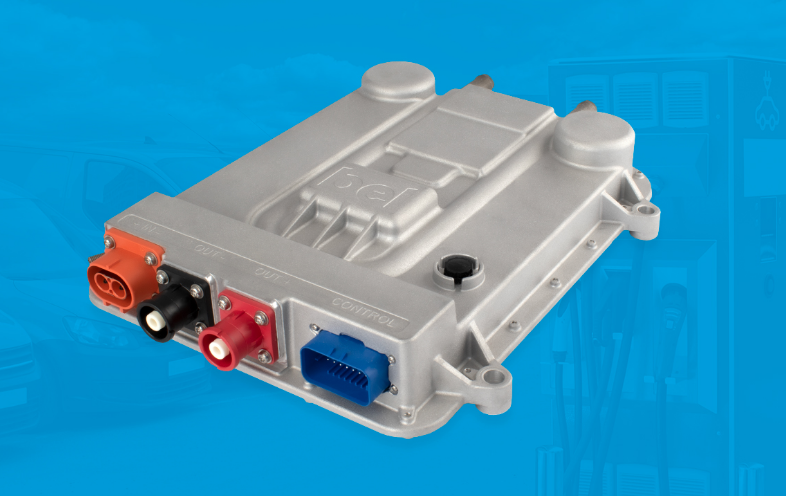

Battery Management Controller

The battery management controller (BMC), a central control unit developed specifically for the PPE, is responsible for the current control required for fast and battery-saving charging. The BMC is completely integrated into the HV battery. The twelve cell module controllers (CMS) send data such as the current module temperature or the cell voltage to the BMC, which sends its information to the HCP 4 high-performance computer. This computer, in turn, sends data to the new predictive thermal management, which regulates the cooling or heating circulation as needed for optimal battery performance.

Thermal Management

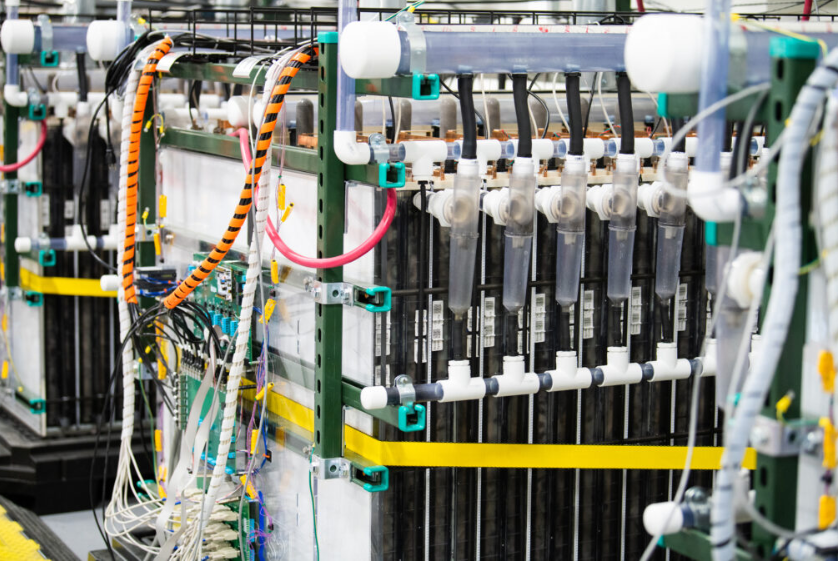

The predictive thermal management uses data from the navigation, the route, the departure timer, and the customer’s usage behavior to calculate the need for cooling or heating in advance. If a customer is driving to an HPC charging station included in the planned route, the predictive thermal management prepares the DC charging process and cools or heats the battery to reduce charging time. If there is a steep grade ahead, the thermal management adjusts the HV battery’s temperature by appropriate cooling to prevent higher thermal stress.

Conditioning

Post-conditioning and continuous conditioning are also new in the PPE thermal management. These functions monitor the battery temperature for the car’s entire service life so the battery is kept in the optimal temperature range even when the vehicle is not moving. This measure also contributes to extended battery service life. The coolant is directed below the modules according to the U-flow principle for high-temperature homogeneity within the battery, increasing performance. The battery cooling plate is also a structural component of the battery, which allows an additional floor panel in the HV space of the battery housing to be eliminated and the thermal connection to the modules to be optimized using a heat-conducting paste.

Source

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?