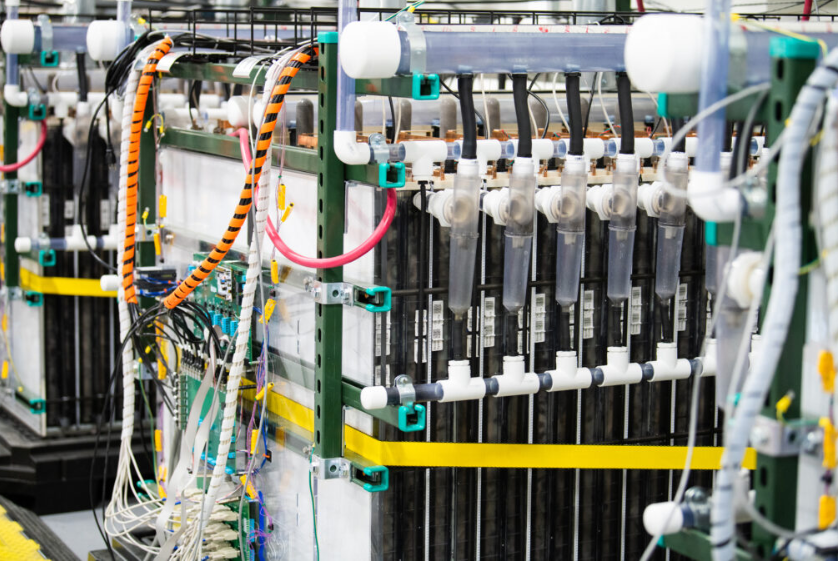

Panasonic Energy Co., Ltd. has announced a partnership with NOVONIX, a materials technology company, to supply sustainable synthetic graphite for electric vehicle (EV) battery production.

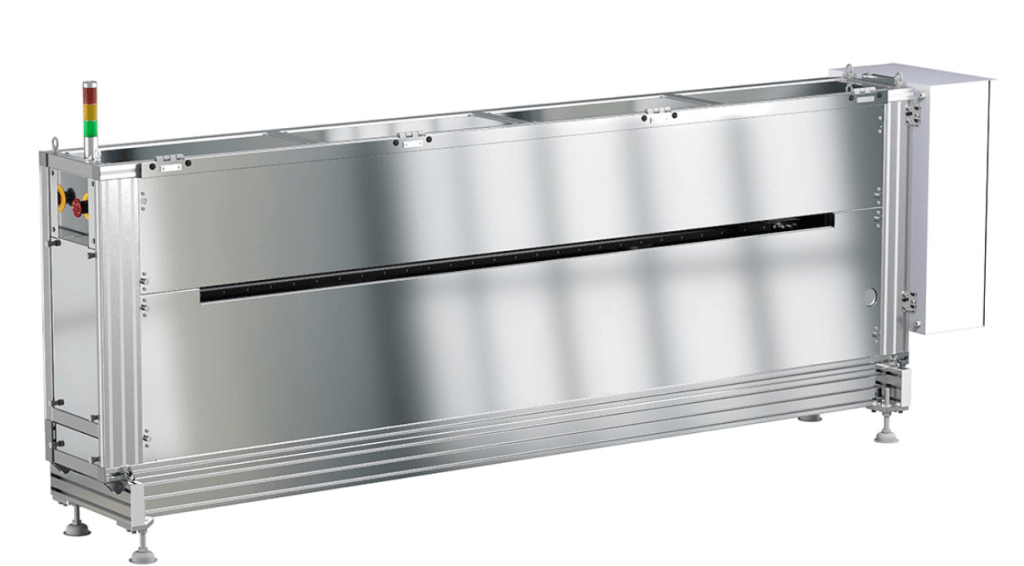

There are two types of graphite for lithium-ion batteries: natural graphite and synthetic graphite. Synthetic graphite offers enhanced battery durability, allowing for reliable performance during repeated charging and discharging cycles. Synthetic graphite is traditionally produced using lengthy high-temperature treatment in an Acheson furnace, lasting 30 days per production cycle, with temperatures reaching up to 3,000℃. However, this production method poses challenges due to its high energy consumption and resulting CO2 emissions, and companies are actively developing innovative production methods to overcome these drawbacks. NOVONIX’s proprietary graphitization furnaces are the first of its kind for large-scale production, enabling efficient mass production of synthetic graphite in just around three days per cycle. This innovation is expected to reduce the levels of CO2 emitted during the production of synthetic graphite compared to conventional Acheson furnaces.

The synthetic graphite will be utilized by Panasonic Energy’s EV battery manufacturing facilities in the U.S., with shipments scheduled to start in 2025 from NOVONIX’s facility in Tennessee. Panasonic will procure 10,000 tons of graphite from NOVONIX over four years.

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

By 2031, Panasonic Energy aims to reduce the carbon footprint of the entire lithium-ion battery supply chain for EVs by 50% compared to 2022 levels.

Source

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?