Lithium-metal batteries promise higher energy densities but the tech is met with a few issues including safety challenges, dendrite formation, and inconsistent cycle life, especially when using a liquid electrolyte.

To solve these, 24M, a licensor of battery technologies, created a new separator technology called Impervio™ which stops dendrites at the source, and a liquid electrolyte called Eternalyte™ which minimizes the reaction between the electrolyte and lithium-metal, mitigating the cycle life degradation. The new breakthroughs like 24M ETOP™ (electrode-to-pack) tech, can be utilized with a 24M SemiSolidTM or conventional electrodes, and when combined, 24M says the suite will help commercialize 1000+ mile lithium-metal battery packs.

Impervio™ Battery Separator

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

The promise: Fundamentally improve safety and eliminate mass recalls by suppressing dendrite formation while detecting and preventing internal shorts.

24M has run comparison tests of baseline NMC/graphite cells with and without Impervio™, and so far it has shown promising results:

In the first test, the cathodes of both cells with/without Impervio were intentionally contaminated with ~1% stainless steel. The baseline cell immediately shorted after formation, while the Impervio cell suppressed the dendrite and pushed past 800 cycles with over 83% capacity retention.

In the second test, 24M intentionally created exposed copper on both cells’ anodes, which led to a rapid soft short of the baseline cell, while the Impervio cell suppressed the dendrites and delivered stable coulombic efficiency while cycling, preventing a soft short between the cathode and anode.

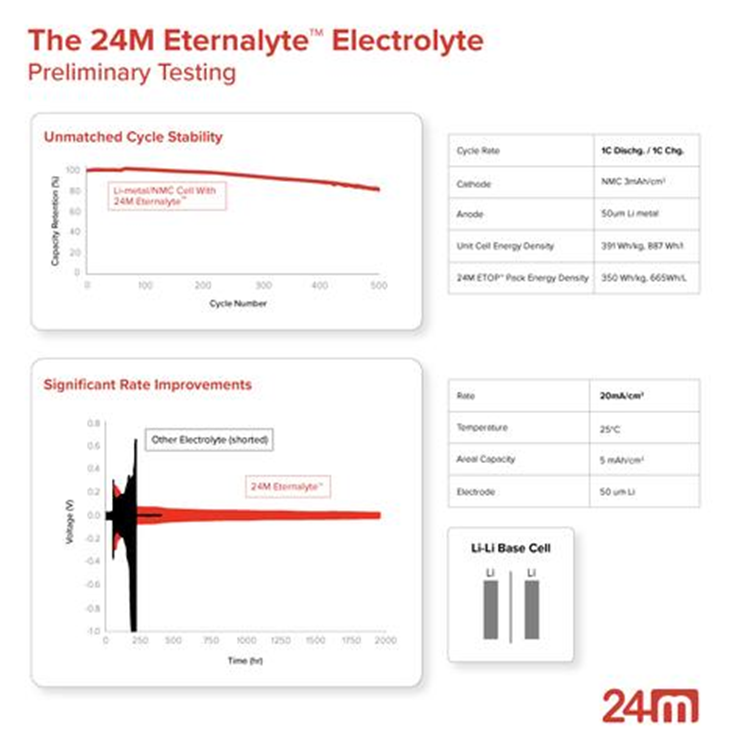

Eternalyte™ Electrolyte

Lithium-metal batteries, especially those with liquid electrolytes, are known for an inconsistent cycle life caused by lithium or other metal dendrites. 24M has reported that Eternalyte™ has achieved the highest cycle stability among liquid electrolyte systems under 20mA/cm2 plating/stripping current.

24M’s internal tests are showing promising improvements:

ETOP™ Electrode-to-Pack Technology

ETOP™ is 24M’s battery packaging system featuring sealed electrodes packaged directly into the battery pack, removing the need for individual cells and modules.

24M’s CEO, Naoki Ota, explained:

“Sony initially commercialized the lithium-ion battery in 1991, and since then, the industry has largely followed their design lead. The approach involves winding electrodes and placing them into a metal casing to construct a battery cell. However, this design is suboptimal for high-voltage applications such as electric vehicles (EVs), which require a voltage range between 300 and 600 volts.

In conventional lithium-ion cell design, each battery cell provides only 3.2 volts (in the case of lithium-ion phosphate chemistry). To achieve a high voltage like 600 volts, one would need to connect almost 200 of these cans in series, where connecting two cans in series would yield 6.4 volts, and so on. Not only does this consume a significant amount of space, but it’s also inefficient.

At 24M, we innovated by creating sealed electrodes or Unit Cells that can be connected in series within a single package. This means that instead of using 200 cans, we might only need one, two, or three cans. This approach reduces costs and increases energy density through our packaging design.”

The 24M ETOP™ system is delivering improvements in several key areas:

You can learn more about 24M’s battery technology on their site here.

Special thanks to Naoki Ota, CEO of 24M for the interview!

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?

Thanks!

You should receive an email from Jeremy@EVTechInsider.com

Can you check to make sure you received it?